Product Description:

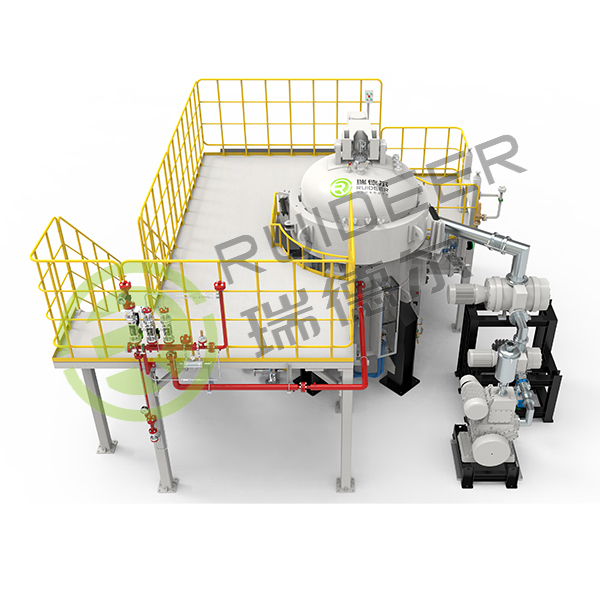

The Ceramic Sintering Furnace is a versatile and advanced piece of equipment designed for precise and efficient sintering processes in various industries. Available in a range of colors including white, gray, black, blue, and green, this Structural ceramic furnace is not only functional but also aesthetically pleasing.

One of the standout features of this Vacuum sintering furnace is its impressive pumping speed. The vacuum degree can reach 5 Pa within 30 minutes after the pump is started, and the limit vacuum value can reach 1Pa after pumping for 60 minutes after reaching 5 Pa. This ensures a quick and efficient sintering process, especially under vacuum conditions.

Operating at a power supply of 380V, this High accuracy temperature control sintering furnace offers precise temperature control capabilities. The temperature control mode is divided into 3 zones, allowing for independent temperature control in each zone. The temperature control is maintained at ≤ ±5 ℃, ensuring consistent and accurate sintering results.

For temperature measuring, the furnace utilizes Ferro Brand MTH Temperature Measuring technology, providing reliable and accurate temperature readings. It is important to note that the temperature measuring ring will be placed on the graphite plate for testing at temperatures ranging from 1350-1550°C.

The Ceramic Sintering Furnace is designed to meet the highest standards of performance and reliability. Whether you are sintering ceramics, metals, or other materials, this furnace offers the precision and control needed for successful sintering processes. With its innovative features and user-friendly design, this furnace is a valuable asset for any industrial setting.

Features:

- Product Name: Ceramic Sintering Furnace

- Advantage: Long Service Life

- Wax collecting rate:≥ 98% (10kg Paraffin Refined Wax , Ar Negative Pressure Dewaxing, Three Averages At Most)

- Pumping speed: The Vacuum Degree Can Reach 5 Pa Within 30 Min After The Pump Is Started, And The Limit Vacuum Value Can Reach 1Pa After Pumping For 60 Min After Reaching 5 Pa (After Drying The Furnace, Under The Empty Furnace, Clean And Cold State)

- Max.loading weight: 50/ 100/ 150/ 300/ 500/ 1200/ 1500KGS

- Working Pressure: 10/20/30/60/100/200 Bar

Technical Parameters:

| Working Pressure |

10/20/30/60/100/200 Bar |

| Atmosphere Control |

Gas Mixing System |

| Pumping speed |

The Vacuum Degree Can Reach 5 Pa Within 30 Min After The Pump Is Started, And The Limit Vacuum Value Can Reach 1Pa After Pumping For 60 Min After Reaching 5 Pa (After Drying The Furnace, Under The Empty Furnace, Clean And Cold State) |

| Color |

White, Gray, Black, Blue, Green |

| Wax collecting rate |

≥ 98%(10kg Paraffin Refined Wax , Ar Negative Pressure Dewaxing, Three Averages At Most) |

| Leakage rate |

≤3Pa/h (Measuring The Limit Vacuum After Drying The Furnace, Stop The Operation Of The Pump Group And Start The Test. Average Within 3 Hours In Empty Furnace, Clean And Cold State) |

| Cooling time of empty furnace |

Empty Furnace, The Cooling Time Of Sintering Temperature From 1450 ℃ To 100 ℃ Is Less Than Or Equal To2/4/ 7 H |

| Effective working zone size |

224/4412/5512/5518 |

| Power |

380V |

Applications:

RUIDEER Ceramic Sintering Furnace is a versatile and reliable product that can be used in a variety of applications and scenarios due to its advanced features and capabilities.

As a Large-capacity chamber furnace, the RUIDEER 224/4412/5512/5518 model series is ideal for sintering a wide range of ceramic materials in different shapes and sizes. Its high loading weight capacity of 50/100/150/300/500/1200/1500KGS makes it suitable for both small-scale and large-scale production environments.

With the ability to operate at working pressures of 10/20/30/60/100/200 Bar, this Protective gas sintering furnace ensures that the sintering process is carried out efficiently and effectively, resulting in high-quality final products.

Moreover, the RUIDEER Ceramic Sintering Furnace is designed to provide precise temperature control independently, with a temperature accuracy of ≤ ±5 ℃. This feature, combined with the use of Ferro Brand MTH Temperature Measuring technology, ensures that the sintering temperature is maintained at the desired level throughout the process.

For applications requiring high-temperature vacuum sintering, this furnace follows specific processes outlined in the final acceptance criteria. The temperature measuring ring is placed on the graphite plate for testing at temperatures ranging from 1350-1550°C, guaranteeing accurate temperature monitoring and control.

In addition, the cooling time of an empty furnace is remarkably fast, with the sintering temperature dropping from 1450 ℃ to 100 ℃ in less than or equal to 2/4/7 hours, depending on the model. This quick cooling time enhances operational efficiency and minimizes downtime between sintering cycles.

Whether used in research laboratories, industrial facilities, or manufacturing plants, the RUIDEER Ceramic Sintering Furnace offers a reliable solution for achieving precise and consistent sintering results. Its power requirement of 380V ensures compatibility with standard electrical systems, making it easy to integrate into existing production setups.

Support and Services:

The Ceramic Sintering Furnace product includes comprehensive technical support and services to ensure optimal performance and customer satisfaction. Our team of experts is available to assist with any product-related inquiries, troubleshooting, and maintenance needs. Additionally, we provide training sessions and resources to help users maximize the efficiency and longevity of their furnace. Our goal is to deliver top-notch support and services to meet the diverse needs of our customers.

Packing and Shipping:

Product Packaging and Shipping:

The Ceramic Sintering Furnace is carefully packaged to ensure safe delivery to your location. It is placed in a sturdy cardboard box with protective foam inserts to prevent any damage during transit. Each component of the furnace is securely wrapped in bubble wrap to avoid any scratches or breakage.

For shipping, we partner with reliable courier services to deliver the furnace to your address in a timely manner. You will receive a tracking number once the shipment is processed so you can monitor the delivery status. Please ensure someone is available to receive the package upon arrival.

FAQ:

Q: What is the brand name of this Ceramic Sintering Furnace?

A: The brand name is RUIDEER.

Q: What are the available model numbers for this Ceramic Sintering Furnace?

A: The available model numbers are 224, 4412, 5512, and 5518.

Q: Where is this Ceramic Sintering Furnace manufactured?

A: This furnace is manufactured in China.

Q: What is the maximum temperature range of this Ceramic Sintering Furnace?

A: The maximum temperature range varies depending on the model, but typically ranges from 1200°C to 1800°C.

Q: Is this Ceramic Sintering Furnace suitable for sintering ceramic materials in a lab setting?

A: Yes, this furnace is designed for sintering ceramic materials and is suitable for use in laboratory settings.